ZMD explosion-proof fluoroplastic self-priming magnetic pump

- Packaging:

- wooden box

- Productivity:

- 500

- Brand:

- BODA

- Transportation:

- Ocean,Land,Air

- Place of Origin:

- china

- Supply Ability:

- 500

- Certificate:

- ISO9901

- HS Code:

- 4101201190

- Port:

- Tianjin,Qingdao,Shanghai

Basic Info

Model No.: BODA-130

Product Description

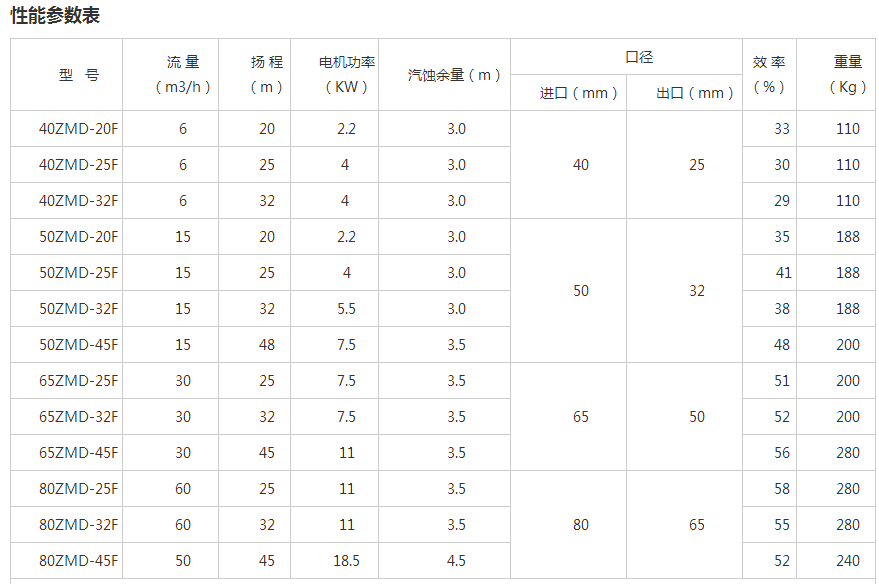

ZMD explosion-proof fluoroplastic self-priming magnetic pump

ZMD fluoroplastic self-priming magnetic pump introduces a new generation of corrosion-resistant self-priming magnetic pump. It not only has the advantages of fluoroplastic magnetic pump, but also has the function of self-priming and no leakage. This is all the fluorine in the past. Plastic magnetic pumps can not be reached, therefore, the series of pumps have been welcomed by the majority of users as soon as they are launched. This series of pumps can be widely used in chemical industry, non-ferrous metal smelting, pesticides, acid and alkali production, paper making, pickling process, rare earth separation, electroplating, electronics, chemical foil, acid and alkali removal industries or work processes. One of the novel products in the structure, and is energy efficient, safe and practical. The pump temperature is -20 ° C -100 ° C. ZMD fluoroplastic magnetic pump adopts motor direct connection structure, supported by intermediate bracket, compact structure, convenient disassembly and maintenance. It uses high-performance magnetic material [NdFeB" to manufacture internal and external Magnets. The isolation sleeve adopts imported non-metallic materials, completely eliminating the general The magnetic pump has magnetic eddy current loss, can transport high concentration, strong corrosive medium with density greater than 1.84t/m3; the main components are steel lining F46, the pump body has high strength, can resist all strong acid and strong alkali corrosion; The advantages of the pump and the self-priming pump are the products developed on the basis of the IMD magnetic pump. The outstanding features are the self-priming function of the self-priming pump and the leakage-free and quiet operation of the magnetic pump. A good alternative to pumping. Particularly suitable for transporting flammable, explosive, toxic, volatile and valuable media. It has been put on the market in batches and has replaced imported magnetic pumps on many projects. ZMD fluoroplastic magnetic pump is widely used in petrochemical, non-ferrous metal smelting pesticides, acid-making alkali, paper making, pickling process, rare earth separation, electroplating, electronics, chemical foil and other industries to absorb and transport corrosive liquid below the pump installation position. It is a novel product in the current magnetic pump variety, which is energy efficient, safe and practical.

ZMD explosion-proof fluoroplastic self-priming magnetic pump design features

ZMD series self-priming magnetic pump combines all the excellent characteristics of the magnetic pump, and has the great advantage of self-priming, self-priming height up to 2-4 meters, fully combined with fluoroplastic self-priming pump and fluoroplastic magnetic pump. All the advantages, not only have the self-priming function, but also cancel the shaft seal, using the magnetic coupling indirect transmission, completely eliminating the phenomenon of dripping.

ZMD series magnetic drive pump adopts the isolation sleeve made of new synthetic material with high strength mechanical properties, completely eliminating the magnetic eddy current phenomenon of the general magnetic pump. With a unique back-pull structure, it is easy for one person to perform internal inspections and parts replacement without dismantling the pipes, which greatly facilitates daily maintenance and repair work.

ZMD fluoroplastic self-priming magnetic pump has all the over-current components manufactured by the world's best corrosion-resistant "plastic king" (fluoroplastic). The pump body is made of metal casing lining polyfluoroethylene propylene (F46), pump cover and impeller. They are all made of metal inserts and fluoroplastics. The isolation sleeves are made of special materials and have high strength mechanical properties, which eliminates the phenomenon of magnetic eddy currents in ordinary magnetic pumps. After the pump is used for the first time before the use, the second and subsequent use does not require liquid filling, and the liquid can be sucked and delivered below the pump installation position. The self-priming, leak-free ZMD magnetic pump is an ideal pump to replace the self-priming pump for the bulky submerged pump.

ZMD fluoroplastic magnetic self-priming pump adopts a unique back-pull structure, which makes it easy for one person to perform internal maintenance and parts replacement without disassembling the pipe, which greatly facilitates daily maintenance and maintenance work. ZMD fluoroplastic magnetic pump product leak-proof design: The shaft seal is cancelled and the magnetic coupling is used to indirectly drive, completely eliminating the trouble of dripping, and never polluting the use site. Since the overcurrent portion of the pump is made of "fluoroplastic alloy". It can continuously transport any concentration of corrosive medium such as acid, alkali and strong oxidant without any damage. ZMD fluoroplastic magnetic pump product operation principle: The driving device is directly mounted on the motor shaft by the active magnet coupling. The pump chamber is completely closed, and the impeller rotation on the rotor combination is indirectly driven by magnetic coupling. ZMD fluoroplastic magnetic pump product pump structure: the pump contact liquid part is fluoroplastic, but the outer shell is made of metal material, so the pump body is enough to bear the weight of the pipeline and resist mechanical shock. ZMD type fluoroplastic self-priming magnetic pump is a direct-coupled motor, supported by the intermediate bracket, easy to install and disassemble, compact, safe and energy-saving.

Precautions for use

Installation method and connection requirements:

1. Make a concrete foundation according to the basic dimensions, and at the same time, bury the anchor bolts. Place the unit on the foundation, align the level of the pump, and tighten the anchor bolts. The pump should be as close as possible to the pool location.

2. The diameter of the inlet pipe of the pump shall not exceed the specified requirements, and the total length of the inlet pipe shall not exceed 5 m. In case of meeting the requirements, the shorter the better. A filter screen must be installed at the bottom of the inlet pipe to prevent excessive particles or debris from entering the pump body and damaging the impeller or affecting the operation of the pump. The filtration area should be 3-4 times larger than the cross-sectional area of the pipeline.

3. The pump must be equipped with a valve in the outlet pipe of the pump to adjust the flow rate so that the pump can work under the specified flow rate to prevent the pump from working after the excess. The diameter of the outlet pipe shall not be less than the specified requirements, and the larger the outlet pipe diameter, the better, if possible. The total length of the outlet tube must be greater than 1.5 times the total length of the inlet tube and, if possible, longer.

4. The weight of the inlet and outlet pipes should not be supported on the inlet and outlet flanges of the pump and should be fixed on the respective brackets. The parts connected to the inlet and outlet pipes must be tight and airtight, otherwise the self-priming function and the normal operation of the pump will be affected.

How to use and maintenance instructions

1. The self-priming magnetic pump is strictly prohibited to transport media containing solid particles or containing crystals. It is not allowed to operate continuously when the discharge port is closed, and a small flow rate is required.

2. When installing the pipeline, first connect the inlet pipe, and then fill the outlet pipe after filling up the liquid.

3. After the installation is completed, connect the power supply, check whether the pump rotation is flexible by jog mode, and check whether the motor steering is consistent with the steering sign.

4. Open the outlet valve by about one-third, and then start the self-priming pump (ie, start the valve), then slowly adjust the outlet valve to make the pump work normally.

5. When infusion, the flow rate, lift and self-priming height must be controlled within the specified range, and the difference can not be too large, otherwise it will cause suction and the pump will not work properly.

6. Self-priming pump is not allowed to produce suction in the work. Once the suction is generated, it must be re-introduced to self-prime. Therefore, the user must have a device that controls the low level or take care of the person to prevent the medium in the pool from being emptied.

7. The self-priming pump cannot transport media that will generate a large amount of bubbles, nor can it transport gas-liquid mixed media.

8. When transporting medium containing easy crystallization, if the pump is not used for a period of time, the pump cavity must be flushed, and the crystallization medium should not be left to prevent damage caused by the pump restarting after crystallization; when used again, the liquid can be added according to the requirements. Suck.

9. When the medium is generally free of crystal medium, if it is used after stopping the pump for a long time, check whether the liquid in the pump body is sufficient before starting. Please make up before you can self-prime.

10. When the pump is used in the environment below the liquid level or used instead of the pipeline pump, the air valve and the buffer valve should not be used. In this case, please remove the air valve and the buffer valve.

11. The check valve of the pump outlet pipe shall not be installed. If it is, the vent hole shall be provided at the lower end of the check valve.

12, self-priming height can be easily calculated: self-priming 3m / medium density = actual self-priming height.

Contact us if you need more details on Self-priming Magnetic Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about ZMD Explosion-proof Fluoroplastic Pump、Self-priming Pumps. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Self-priming Pump