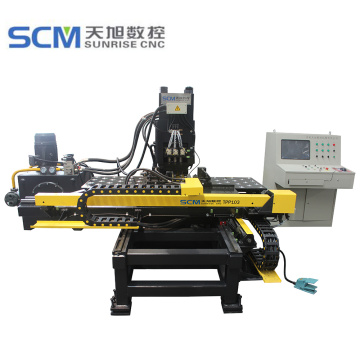

CNC Punching Machine for Plates

- Productivity:

- 200 Sets/Year

- Place of Origin:

- China

- Supply Ability:

- 200 Sets/Year

- Certificate:

- GS, ISO 9001

Basic Info

Model No.: TPP103

Product Description

Model NO.: TPP103

Power Source: Hydraulic Pressure

Precision: High Precision

Certification: GS, ISO 9001

Condition: New

Trademark: SUNRISE

Transport Package: Plywood Case

Specification: 3200mm*3000mm*1900mm

Origin: China

HS Code: 8462411900

Applicable Industry:Special CNC machine for punching and marking of steel plates in the field of steel tower industry. It is also used to punch and mark of steel plates of other industries.

Product Feature:

- The machine-frame is made by C-type plate welding, with good rigidity and big handling space. The machine sets three die-stations (two punching, one marking), automatic switching die-stations. Clamping system can be adapted to different workpiece, with reference block, and workpiece supported by rolling-ball working table. X & Y axis action controlled by servo motor and ball-screw driving and PLC, control the position of punching, so as to make the whole machining process automatically. Operator input the workpiece program, it can be used repeatedly2. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision.

6. With self-diagnosis failures function.

7. X, Y axis are driven by servo motor + ball screw + linear guide, the precision is better.

8. POWER: Three phase four wire systems

AC Voltage: 380V (±10%) or 415V for India

Frequency: 50Hz

Local working temperature: 0-40ºC

Special advantages:

Hydraulic station adopts dual-pump and single motor. Punching speed is faster than other company's, so it is more efficient and improve the workshop ability.

It adopts sleeve-type coupling for all pipelines, which avoid leakage.

Specifications:

| Model | TPP103 |

| Max size of work piece L×W(mm) | 1500×800 |

| Max. punching diameter (mm) | Φ26 |

| Plate punching thickNess (mm) | 5~25 (Q235), 5-20(Q420) |

| Punching force (kN) | 1000 |

| Marking force (kN) | 800 |

| Min. distance between hole and plate edge (mm) | 25 |

| Character size(mm) | 14×10×19 |

| Qty. of character | 12 |

| Die-stations | 3 |

| Programming mode | Auto CAD or lofting software |

| Overall dimensions L×W×H (mm) | About 3200×3000×1900 |

| Machine weight (Kg) | About 5420 |

Main Components :

| NO. | Name | Manufacturer | ||

| Main Electric Components | ||||

| 1 | PLC | Japan Mitsubishi | ||

| 2 | Servo Motor | Japan Panasonic | ||

| 3 | Servo Driver | |||

| 4 | Business Computer | LCD screen | China Lenovo | |

| 5 | Proximity Switch | Normal open | AUTONICS | |

| 6 | Normal close | |||

| 7 | Low-voltage electrical components (switches, buttons, circuit breakers, indicator lights) | German SIEMENS | ||

| Main Hydraulic Pressure Components | ||||

| 1 | Electromagnetic hydraulic Valves | Italy ATOS | ||

| 2 | Vane pump | America DENISON | ||

| Main Pneumatic Components | ||||

| 1 | Punching Unit | Padding Block Cylinder | AIRTAC | |

| 2 | Magnetic Switch | AIRTAC | ||

Spare parts list :

| NO. | Name | Material | Qty. | Remark |

| 1 | Punch head | T10A | 12 | Ф17.6, Ф21.6, Ф25.6 |

| 2 | Cavity die | T10A | 24 | Ф18.7, Ф19.2, Ф22.7, Ф23.2, Ф26.7, Ф27.2 |

| 3 | Punch head pole | T10A | 3 | Including installed in machine |

| 4 | Character box | T10A | 2 | Including installed in machine |

| 5 | Characters | T10A | 1 | Including installed in machine |

| 6 | Punch head nut | 40Cr | 3 | Including installed in machine |

| 7 | Upper claw | T10A | 3 | Including installed in machine |

| 8 | Nether claw | T10A | 3 | Including installed in machine |

| 9 | Proximity switch | Normal open | 1 | AUTONICS |

| 10 | Proximity switch | Normal close | 1 | AUTONICS |

| 11 | Drill holder | For TPPD103/104 | 1 sets | Made in China |

| 12 | Linear bearing of clamps | 1 | ||

| 13 | Air connectors/Pipe joints | 1 set | ||

| 14 | Tools | 1 set | For installation | |

| 15 | Spanner for punch head | 1 | For installation | |

| 16 | Spanner for double nipple | 2 | For installation | |

| 17 | Standby paint | 1 | 1pail for main color and 1pail for warning color | |

| 18 | Operation Manual | 2 sets | ||

Product Categories : Punching Machine > Plate Punching Machine

Hot Products

Isotropic high practical fridge magnet resinD60D50T10 High Remanence Sintered Ndfeb Magnet PermanentIsotropic AlNiCO LN10 & LNG13 Speedometer MagnetsHot sale customized High Quality Electric Magnet MotorInjection Molded Anisotropic Ferrite Magnets/ Nylon6 MagnetsTrapezoidal Rare Earth Magnet as Customersflexible magnet rubber magnet PVCBonded NdFeB MagnetBar Neodymium MagnetBonded Neodymium MagnetRing Neodymium-Iron-Boron MagnetNeodymium arc magnets for magnet generatorNdFeB Magnet with Ni CoatingN40 Neodymium Cylinder Magnet with Nickel PlatingD25x5mmx6mm Sunk Neodymium MagnetNeodymium D10mm Disc Magnet With NiCuNi Coating for sale